The Buckeye Denailer

The Ultimate Nail Puller for Removing Hardware in Reclaimed Wood

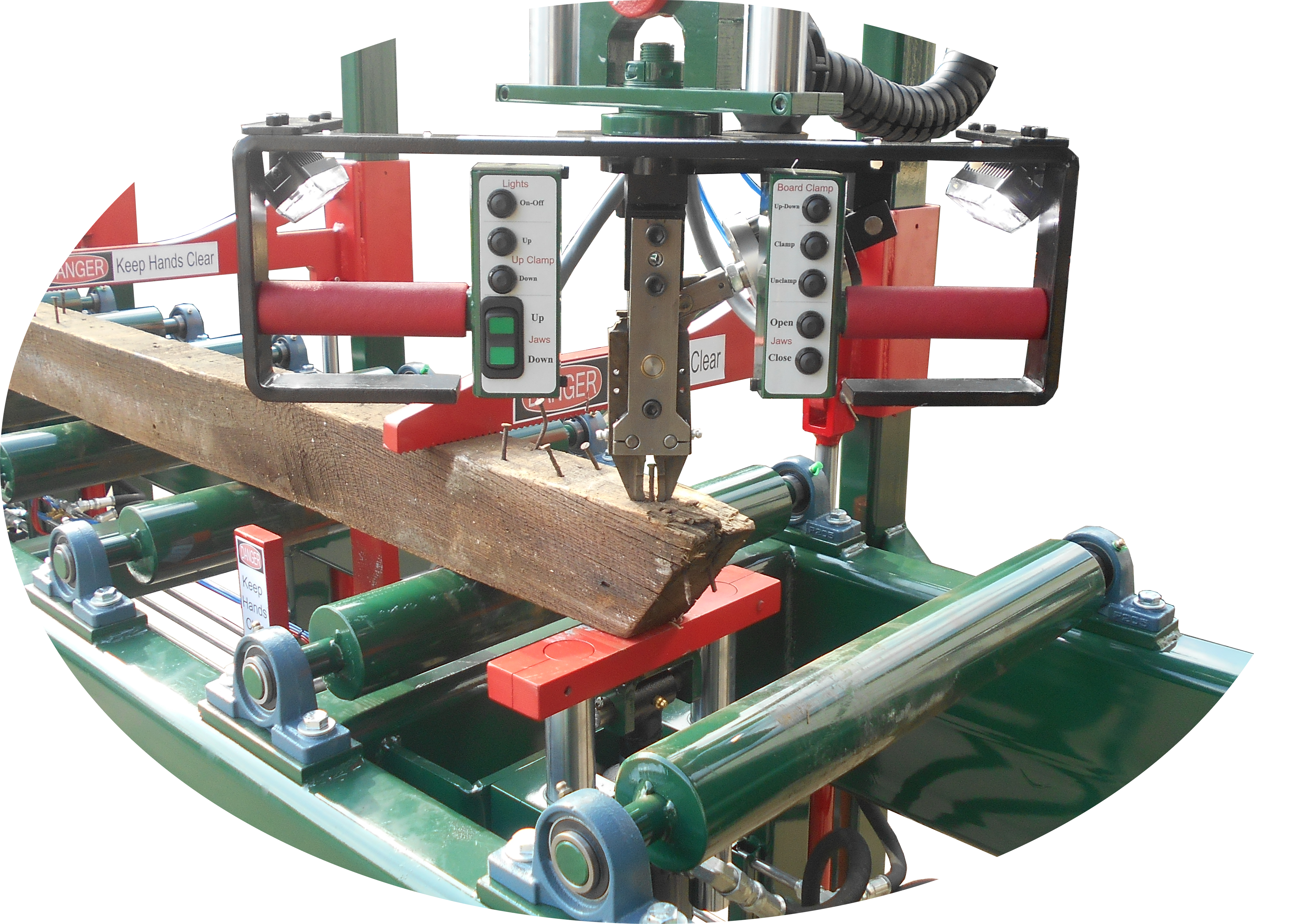

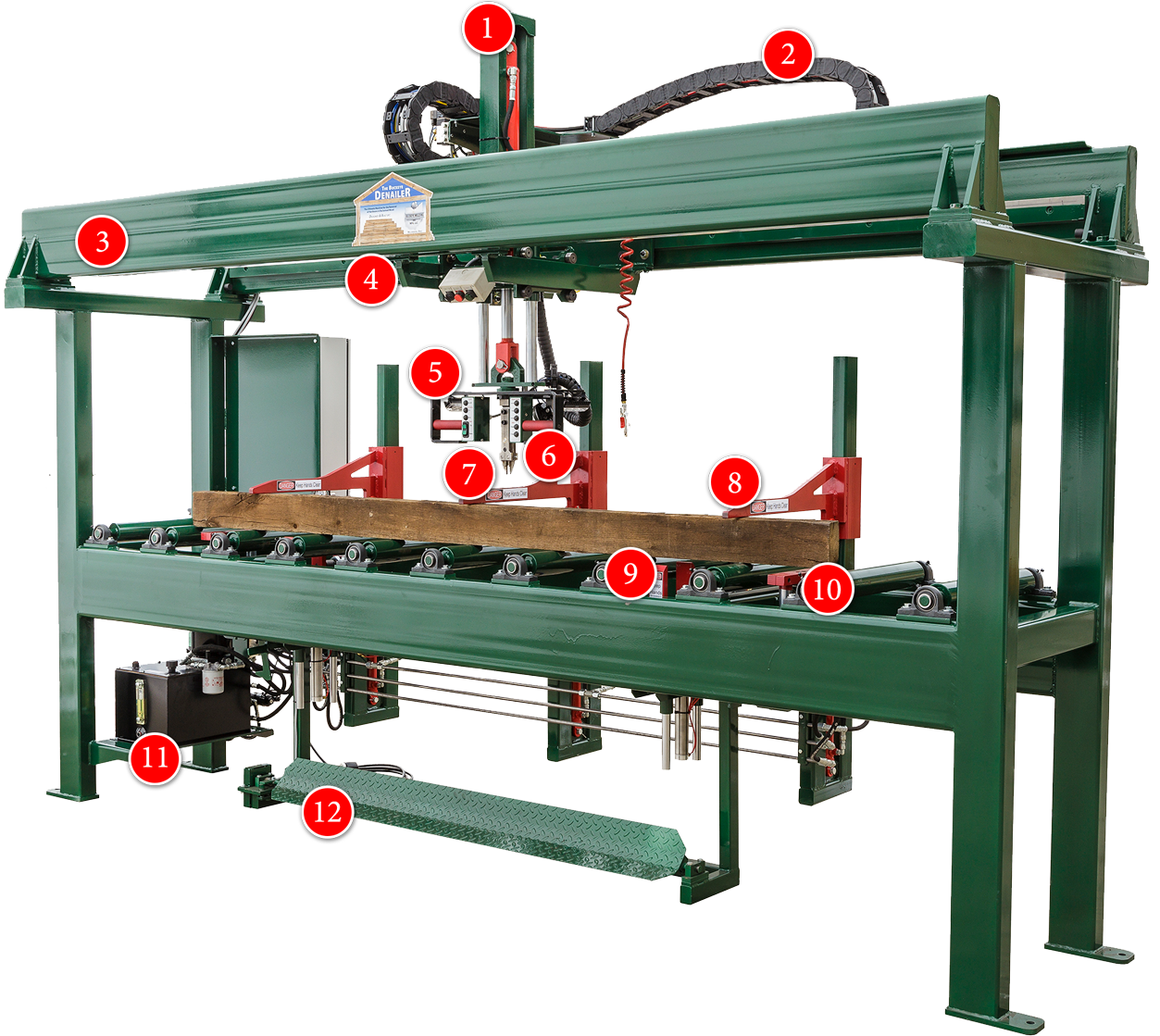

“The Buckeye Denailer” is a high quality built, manually operated machine that is used to pull nails and misc hardware from reclaimed lumber and barn beams.

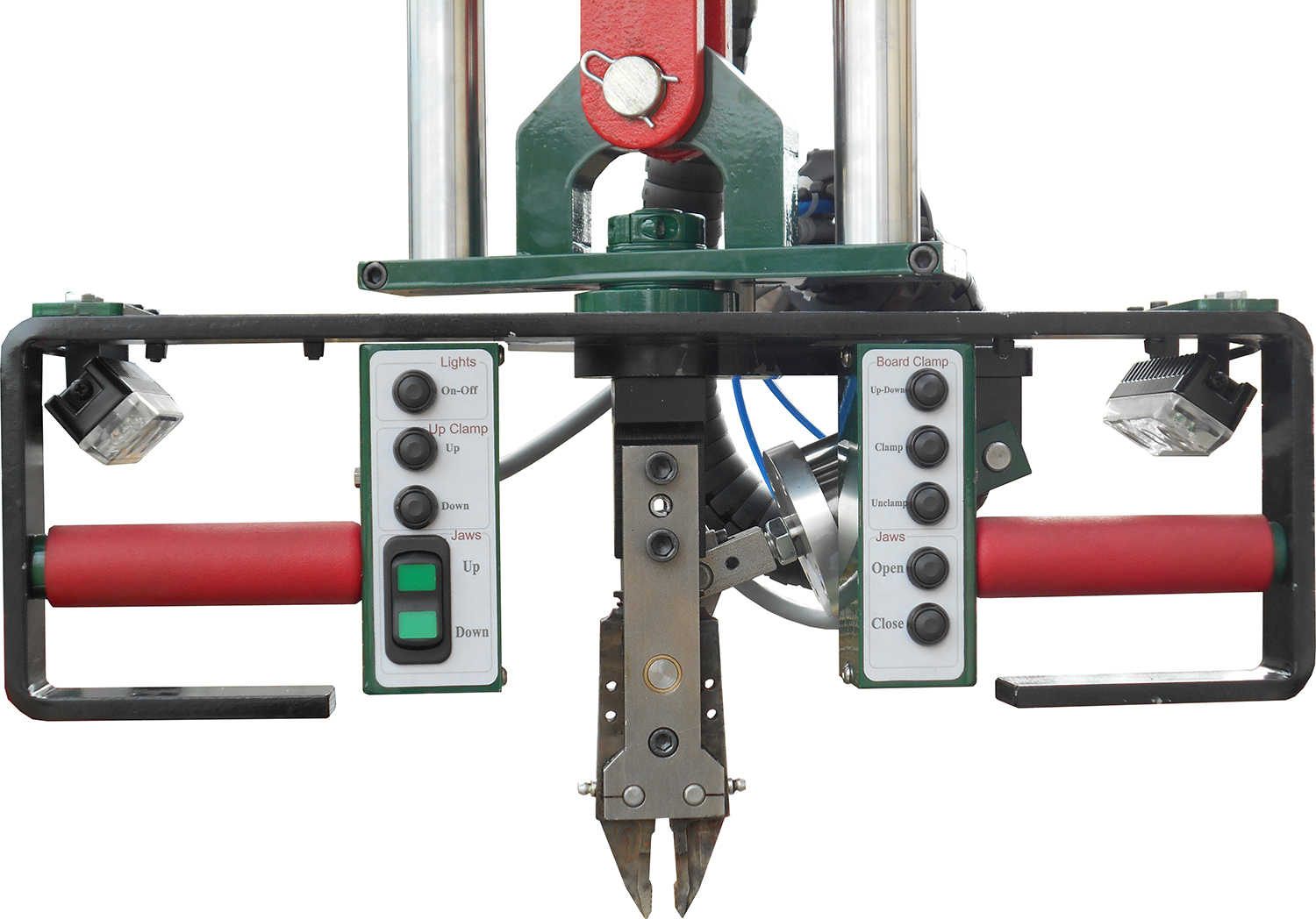

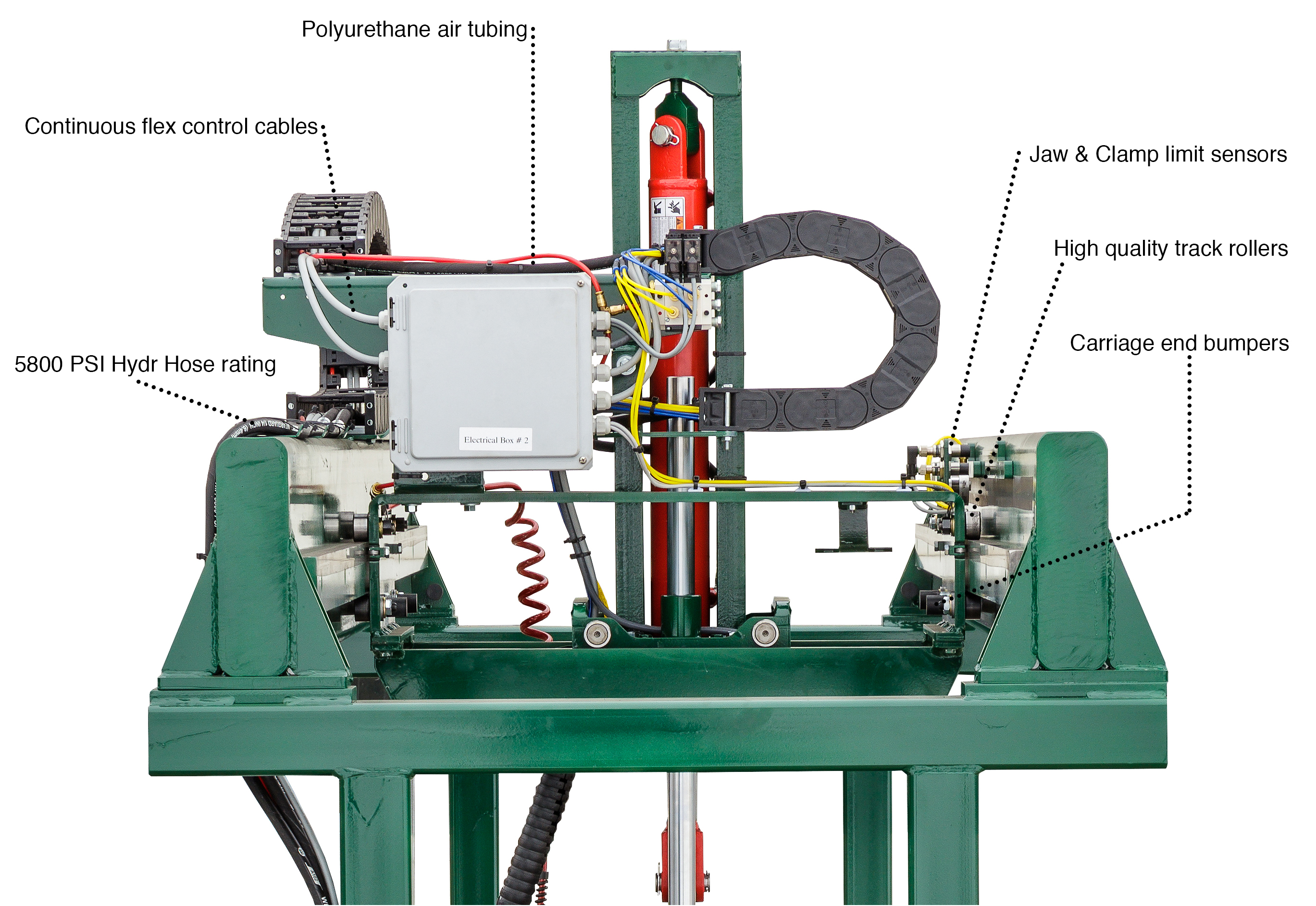

“The Buckeye Denailer” uses a set of custom, machine-hardened steel jaws to pull the nails. Riding on a 2-axis carriage, the jaws are pushed into the lumber by a vertical high pressure hydraulic cylinder, then clamped on hardware for extracting. The lumber is held in place by 3-clamps.

- Very easy to operate

- Enables you to work long shifts without being tired

- Takes the place of 6 or more employees extracting by hand

- 50% less wood pullout

- Very short payoff period

- Very low maintenance costs

- Very easy jaw replacement when needed

- Electric power supply option

- Optional “Power Assist” add-on to make carriage movement even easier

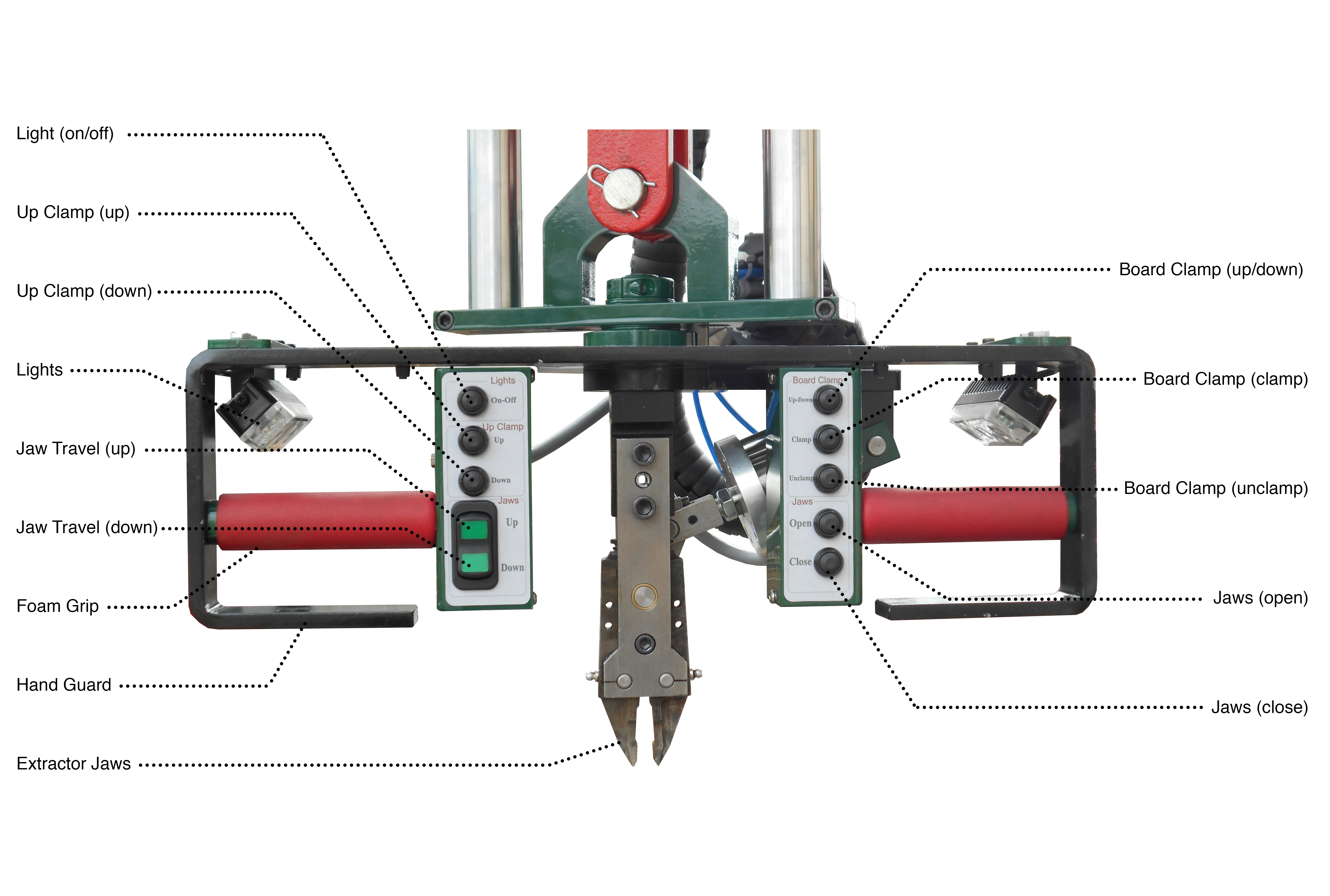

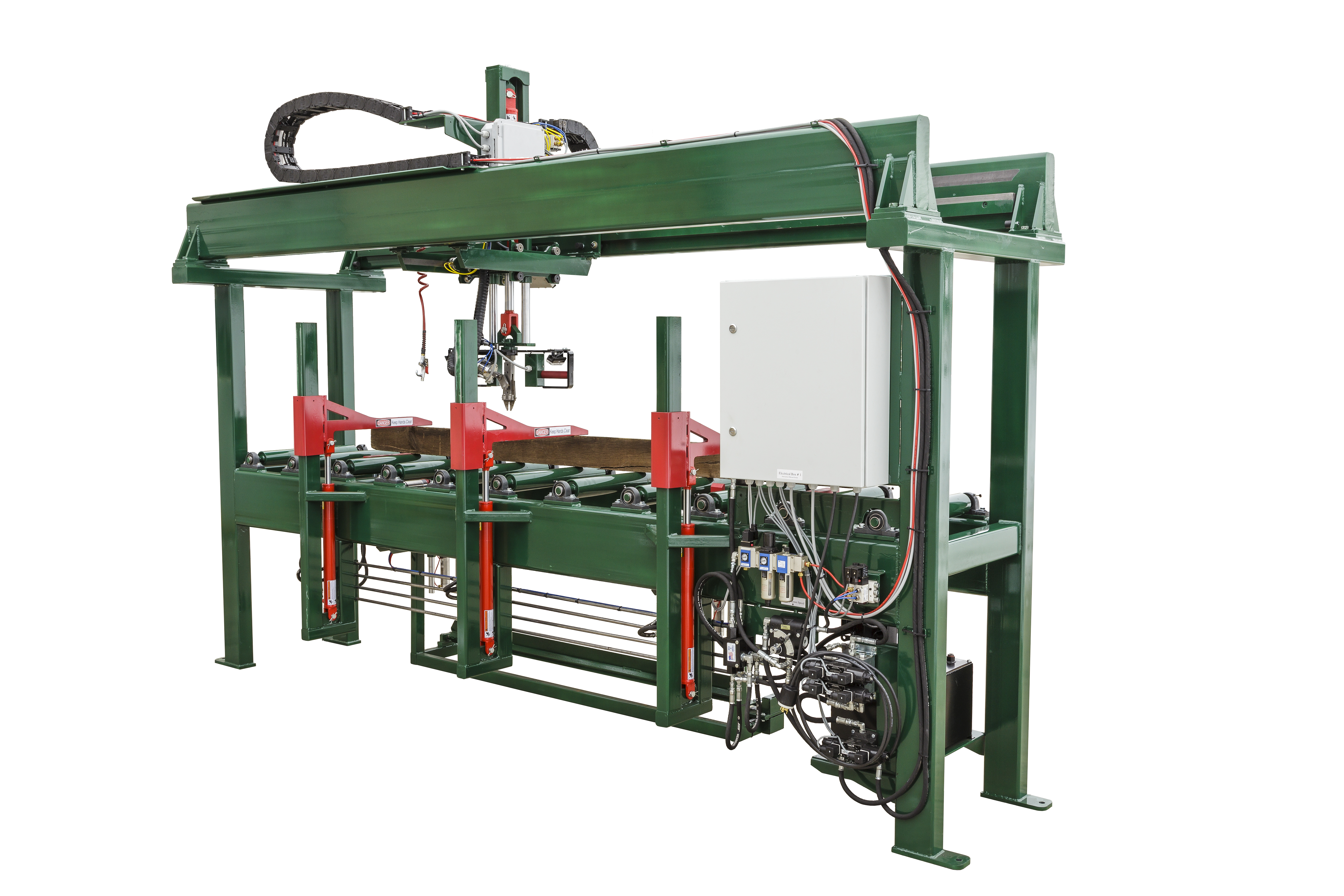

Key Features of the Denailer

- 1. High pressure hydraulic cylinder to push extractor jaws into lumber

- 2. Hose/Wire carrier

- 3. Heavy duty tubular frame

- 4. Manually positioned carriage

- 5. Lights on work piece

- 6. Swiveling control handle

- 7. Hardened extractor jaws for long life (easily replaced when needed)

- 8. Hydraulic clamps

- 9. Board clamps

- 10. Rollers for positioning big beams

- 11. 110 VAC powered hydraulic pump

- 12. Foot pedal for hands-free repositioning and clamping lumber

Available Options for Denailer

Power Options

| Voltage | Phase | Amperage | Jaw Travel Speed |

|---|---|---|---|

| 110 VAC | 1 Phase | 25 | 1.255 inches per second |

| 240 VAC | 3 Phase | 12 | 1.961 inches per second |

Power Assist

An optional add-on to "The Buckeye Denailer" for effortless left or right initial start off movement of carriage.

The "Power Assist" is an option for "The Buckeye Denailer" machine to assist in the left & right movement of the main carriage.

"Power Assist" is a maintenance free add-on consisting of air cylinders, controlled by a programmable logic controller, to grip the frame and "shove" the main carriage left or right. Operator has 2 pushbutton switches, 1 on each handle for left or right movement.

- Push buttons are located on each handle

- Starts off initial movement of carriage

- Moves carriage in little increments if needed

- Easily installed by customer

Machine Specifications

Machine Dimensions

Height 104”

Width 42”

Length 152”

Max Beam Size

Height 16”

Max Carriage Travel

Horizontal 14 x 114”

Vertical 18”

Air Power Supply

Min PSI 90

Max PSI 130

CFM 2.5

Jaw Travel Max Speed

Up 2.57 IPS

Down 1.96 IPS

Jaw Opening

Max .370” (approx)

Jaw Extracting Depth

Max 1.500”

Jaw Force Max

Up 5649 lb.

Down 8099 lb.

Hydraulic Oil

Oil Type AW 32 Hydr. Ol

Filter ZINGA BE-10-18

$ Labor Savings $

6 people - by hand

6 people $35,000/year= $210,000

Chisels, hand tools,misc - $300

Total Yearly cost $210,300!

1 person - Buckeye Denailer

1 person $35,000/year = $35,000

Jaw Replacement x 4 = $1,300

Electric Power = $850

Air Power = $750

Maintenance/grease = $20

Total Yearly cost $37,920

Contact Us

For more information on the Buckeye Denailer, please get in touch with us.

Yoder Dry Kiln

29881 SR 643

Fresno, OH 43824